The Dawn of Robotic Mass Production: A New Era Defined by Design

- Home

- The Dawn of Robotic Mass Production: A New Era Defined by Design

- August 24, 2023

- by Kristine T.

- Robotics

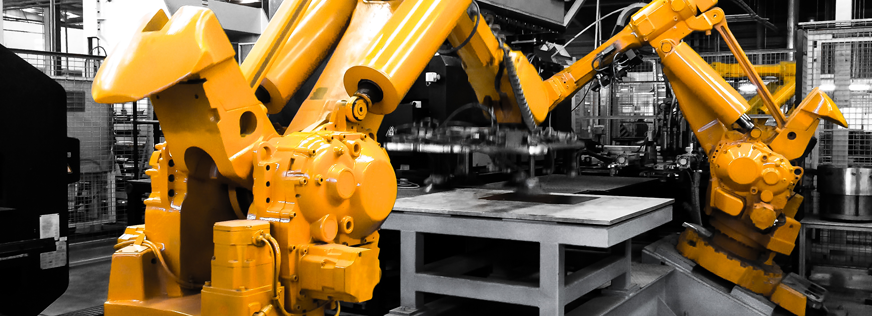

In the age of rapid technological advancement, the lines between the digital and physical worlds are becoming increasingly blurred. A recent article from The Economist sheds light on a groundbreaking shift in the realm of manufacturing: "If it can be designed on a computer, it can be built by robots."

The Old Guard of Mass Production

For decades, mass production has been the backbone of the global economy. The assembly line, introduced by Henry Ford in the early 20th century, revolutionized the way products were made, allowing for faster, more efficient production. However, this method, while efficient, often lacked flexibility. Customization was a luxury, and any deviation from the standard design required significant time and resources.

The Digital Transformation

Enter the age of digital design. With the advent of sophisticated design software, creators can now visualize and modify their creations in real-time, allowing for unparalleled customization and innovation. But until recently, the leap from digital design to physical product still faced the constraints of traditional manufacturing.

The game-changer? Robotics. As the article suggests, powerful new software is rewriting the rules of mass production. If a product can be visualized and designed in a digital space, robots can now bring it to life in the physical world.

The Implications

This shift has profound implications for industries worldwide:

1. Customization on Demand

Consumers can expect products tailored to their specific needs and preferences, without the extended wait times or exorbitant costs previously associated with custom-made items.

2. Reduced Waste

With precision robotics, there's a significant reduction in material waste, leading to more sustainable production practices.

3. Economic Shifts

As robots take on more of the manufacturing workload, there will be a need for skilled workers to design, program, and oversee these robotic systems. This could lead to a shift in job markets and economic structures globally.

4. Rapid Prototyping

Innovators and entrepreneurs can bring their ideas to life faster than ever before, leading to an explosion of new products and solutions in the market.

The Road Ahead

While the potential of robotic mass production is vast, it's essential to approach this new era with a balanced perspective. As with any technological advancement, there will be challenges to overcome, from ensuring equitable access to these technologies to addressing the potential job displacements in traditional manufacturing sectors.

However, one thing is clear, the future of manufacturing is here, and it's defined by the limitless possibilities of design. As we stand on the cusp of this new era, it's an exciting time to be a creator, innovator, and consumer. The future is not just being written; it's being designed.