Modern Engineering Enhancements in Production

- Home

- Modern Engineering Enhancements in Production

- Oct 17, 2023

- by Kristine T.

- Product Design

In today's fast-paced industrial landscape, the drive to enhance production efficiency and quality has never been more critical. Modern engineering technologies have ushered in a new era of manufacturing, one that is characterized by innovation and precision. This article explores the latest engineering enhancements in production processes that are transforming the way we make things.

The Digital Revolution in Manufacturing

The heart of modern engineering in production is the incorporation of digital technologies. This transformation is not merely an evolution; it's a revolution. Digital technologies have disrupted traditional manufacturing processes, making them smarter, more efficient, and more flexible.

• Smart Manufacturing: Smart manufacturing is a concept that revolves around the use of data and automation to optimize the production process. It involves interconnected systems, Internet of Things (IoT) devices, and artificial intelligence to monitor and control production in real-time. By leveraging data analytics, manufacturers can make informed decisions, leading to increased efficiency and reduced downtime.

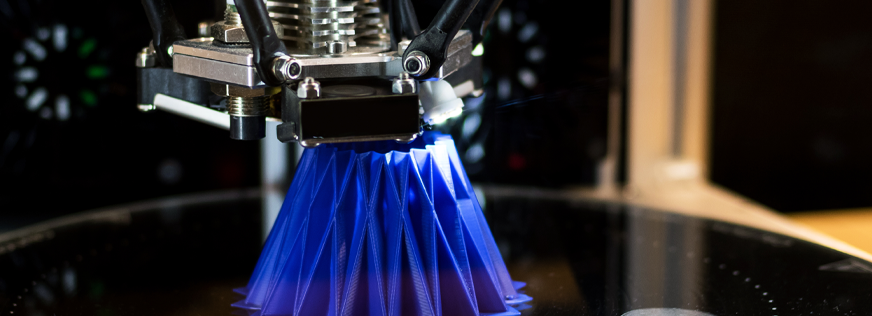

• 3D Printing: 3D printing, or additive manufacturing, has been a game-changer in various industries. It allows for the creation of complex, customized, and intricate parts with unmatched precision. This technology is not only cost-effective but also accelerates the production process, reducing lead times significantly.

Enhancing Product Design

Innovation in engineering is not limited to the production process itself; it extends to product design and development. Modern engineering has brought about a paradigm shift in how we approach designing products.

• Generative Design: Generative design is a cutting-edge approach that uses algorithms to create designs. It starts with defining the problem, constraints, and objectives, and the software then generates multiple design options. Engineers can then choose the most suitable design from these options, optimizing products for performance and efficiency.

• Virtual Prototyping: Virtual prototyping enables engineers to create and test product designs in a digital environment. This reduces the need for physical prototypes, saving both time and resources. It also allows for the identification and resolution of potential issues before production begins, ensuring a smoother production process.

Automation and Robotics

Automation and robotics play a pivotal role in modern engineering, especially in production facilities. They not only improve efficiency but also enhance workplace safety.

• Collaborative Robots: Collaborative robots, often referred to as "cobots," are designed to work alongside human operators. They can handle repetitive and strenuous tasks, allowing human workers to focus on more complex and creative aspects of the job. This not only improves efficiency but also reduces the risk of workplace injuries.

• Automation in Quality Control: Automation is also transforming quality control processes. High-precision sensors and machine learning algorithms are used to inspect products with unmatched accuracy. This not only ensures that the final product meets stringent quality standards but also reduces the likelihood of defects escaping the production line.

Sustainability and Eco-Friendly Practices

Modern engineering in production isn't just about improving efficiency; it also emphasizes environmental responsibility.

• Green Manufacturing: Green manufacturing focuses on reducing the environmental footprint of production processes. This includes using sustainable materials, optimizing energy consumption, and minimizing waste. By adopting green manufacturing practices, companies can not only reduce their impact on the environment but also cut costs in the long run.

• Circular Economy Practices: The circular economy model emphasizes reusing, recycling, and refurbishing products and materials. Modern engineering has made it possible to design products with this model in mind, ensuring that materials can be easily repurposed or recycled at the end of their life cycle.

The Future of Production Engineering

The engineering enhancements we've discussed are just the tip of the iceberg. As technology continues to advance, the possibilities in production engineering are limitless. This presents an exciting opportunity for businesses to stay ahead of the curve and remain competitive in their respective industries.

At Design to Product Ltd, we understand the transformative power of modern engineering in production. We are committed to helping businesses harness the latest technologies and innovations to achieve their production goals. Our team of experts specializes in smart manufacturing, generative design, automation, and sustainable practices, ensuring that your business stays at the forefront of industry advancements.